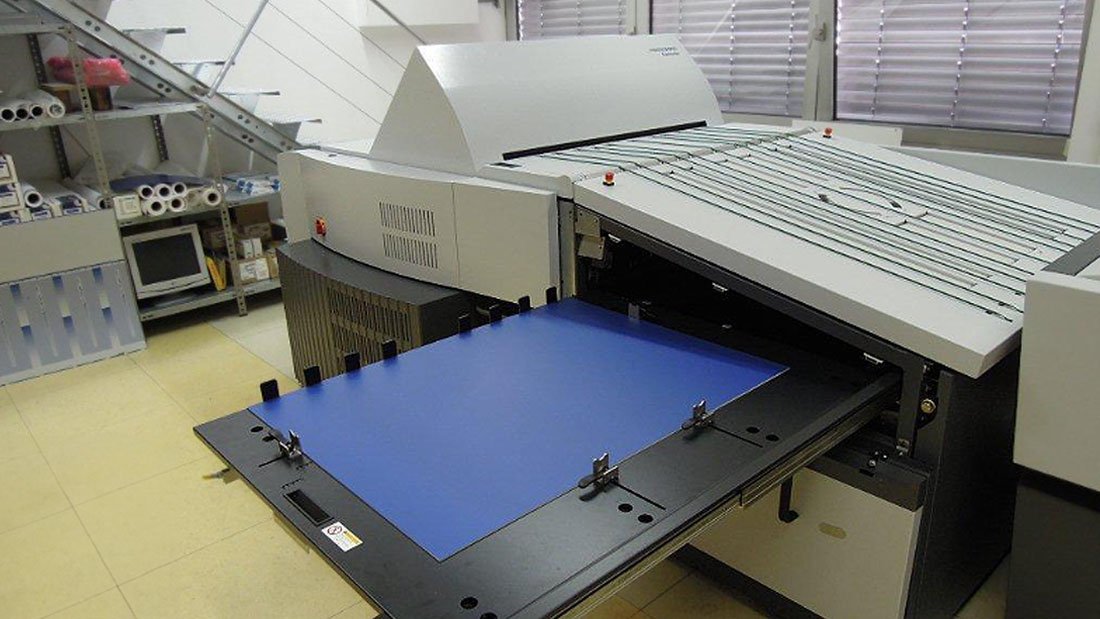

Upgraded Heidelberg Suprasetter

Learn about Spectrum’s upgraded Heidelberg Suprasetter A106/106, it’s capabilities and benefits.

Spectrum Marketing has taken its printing capabilities to the next level with an upgrade to our Heidelberg Suprasetter A106/106 platesetter. This enhancement brings greater precision, speed, and reliability to our prepress operations, allowing us to produce plates faster and with even higher quality. The Suprasetter A106/106 now integrates advanced laser technology and improved energy efficiency, enabling us to meet tighter deadlines while reducing our environmental footprint. With this state-of-the-art upgrade, Spectrum Marketing is committed to delivering exceptional printing solutions, ensuring that our clients receive outstanding results every time.

Peak performance platesetters in medium-size format. Suprasetter A106/106.

The Suprasetter A106/106’s modular design offers maximum flexibility for medium-format production needs. Its Intelligent Diode System (IDS) significantly reduces production losses, while the integrated cooling system protects against performance issues caused by external temperature fluctuations.

Laser technology

Smart Plate Handling

The Suprasetter A106/106 enhances plate handling with Smart Plate Handling across all upgrade levels for maximum convenience. The Dual Cassette Loader (DCL) system is positioned at the back, while the Auto Pallet Loader (APL) is docked at the front using a foldable transport bridge. An integrated plate conveyor within the auto loader further optimizes space, reducing the system’s overall footprint. This setup offers a clear advantage over conventional systems, which often limit bypass functionality and require an external conveyor. The Suprasetter’s design also enables quick manual plate loading, ensuring both automatic and manual loading are equally efficient.

Temperature stabilizer

The temperature of all imaging-related components is kept constant, ensuring that printing plates are always imaged under consistent conditions—a feature especially valuable for plate remakes. By preventing deviations due to ambient temperature fluctuations, this system preserves high register accuracy in the plates, leading to faster press makeready and minimal waste.

Internal punching system

Debris removal system

The Debris Removal System is an optional vacuum and filtration setup designed to clear away loose particles and dust. With this system installed, the Suprasetter A106/106 is fully prepared to handle ablative plate processing.